Tea Processing Gyokuro

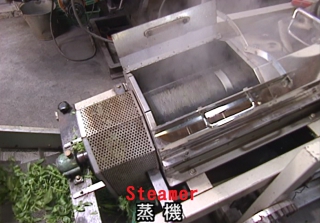

For gyokuro, immediately after picking, tea leaves are steamed to stop oxidation (the majority of Japanese green tea processing starts in this manner).

![]()

The leaves are moved from the steamer to the coarse kneading machine. After exiting the steamer, tea leaves contain more than 80% water. With special techniques, this amount of water can be increased or decreased.

![]()

In the coarse kneading machine, leaves are kneaded, broken into small pieces and at the same time, dried at 35˚C”

![]()

After coarse kneading, the next step is crumpling.

![]()

In the secondary kneading, the coarsely kneaded and crumpled tea leaves are further processed and dried

![]()

Once secondary kneading is complete, the leaves are moved to the final, precise kneading machine.

![]()

Precise kneading is the final step. Here, the leaves are processed into slender pieces and dried at the same time.

![]()

In precise kneading, the skill of the tea processor can be seen. Ranging from fixing clogs to adjusting the speed and temperature of kneading, this process is carefully regulated to ensure production of a high quality tea.

![]()

After precise kneading, the tea leaves are put into a dryer. From raw tea leaves to the finished, processed tea leaves, water is gradually removed. The final weight of the processed tea leaves is approximately 1/5 of the original.

![]()

In this form, gyokuro is known as aracha (unrefined tea). From the manufacturing plant, these leaves undergo additional processing at a tea wholesaler before reaching the hands of consumers.

![]()